15 Apr Choosing the Right Steel Shot Blast Media

Shot blasting is a technique often used to clean, descale, deburr, remove rust, peen, texture or provide a uniform surface finish for metal parts. The process generally involves propelling or blasting spherical shot made of steel, carbon or other materials against the part with high-pressured air or thrown with a spinning wheel.

Shot blasting steel media is what many people choose for the process since it can do everything from peening to polishing, depending on the size and hardness of the chosen shot. This range of capabilities makes it crucial to pick the correct media to achieve optimal results for different parts.

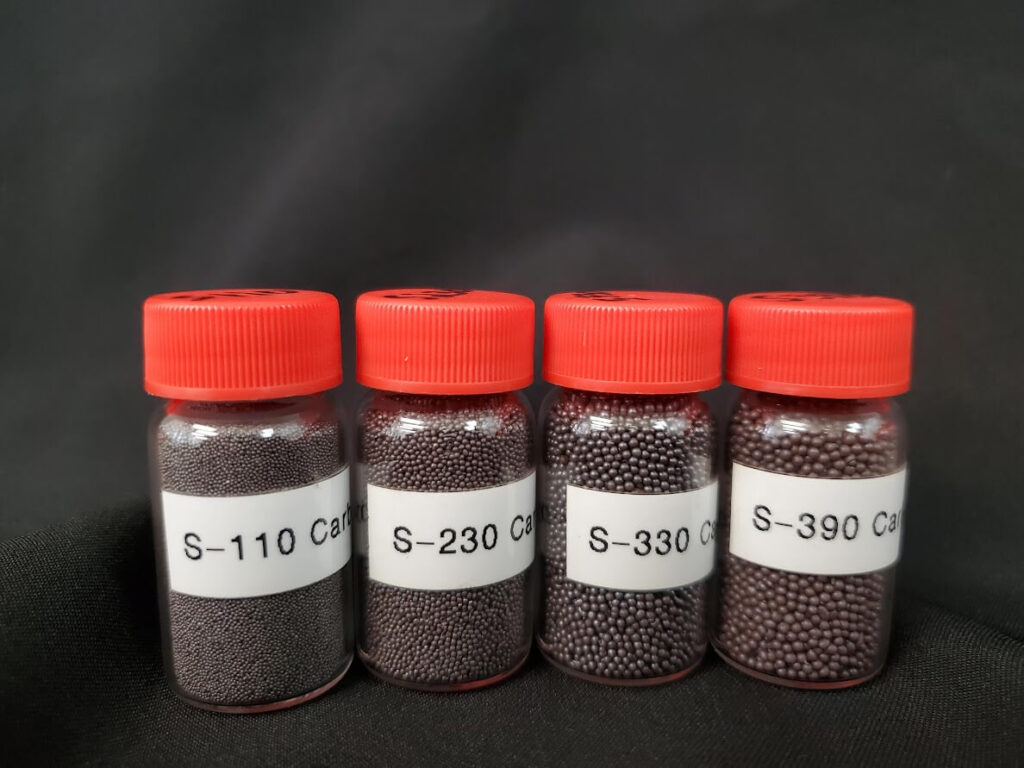

Types of Shot Blast Media

Since different materials have different effects and capabilities, a number of different types of shot media can be used in the blasting process. Some of the most common Eaglemaster uses include:

- Steel

- Stainless steel

- Carbon

- Ceramic

- Glass

- Plastic

Some shot media is best used for polishing or removing thin layers of unwanted residue, like glass or ceramic. Materials like steel shot can be used, especially in larger and heavier sizes, to remove thicker layers of paint, rust and debris while also strengthening the parts being shot. While it’s unlikely damage will occur, it should be noted that picking the incorrect shot media could result in unwanted results.

Factors Influencing Media Selection

There are a variety of things you should consider for media selection, even if you’ve settled on a particular material that you want to use. For steel shot blast media, the main two things to keep in mind are size and hardness.

Media Size

In general, larger sizes of the steel shot are used when thicker layers of unwanted coatings, like paint or dirt, need to be removed. This more aggressive sized shot is also liable to create a more textured surface, which is not always the desired outcome. As a rule of thumb, choosing the smallest shot size that will accomplish what you need it to do is the best way to make sure your parts end up clean and with the desired uniform surface finish.

Media Hardness

Choosing the correct hardness of steel shot is necessary for ensuring the blasted parts ends up with the correct finish. As a rule, softer shot media will result in a more polished, smooth finish, while harder media will leave a rougher, more textured finish. While not likely, if you use media that is too hard, your parts could risk substrate damage, so it is important to carefully consider how hard the shot is that you choose.

Selecting the Right Steel Shot Blast Media

The first step in choosing the right steel media for your shot blasting needs is to decide what the desired end outcome will be. Whether it’s cleaning, preparing for next manufacturing steps, removing paint, peening or something else, knowing your end goal will ensure you use the correct steel shot.

For example, if your parts are heavy-duty and are in need of cleaning and surface texturing for coating or further manufacturing, a harder and larger shot media will serve you well. Conversely, if your parts need polishing and thin layers of residue removed, smaller and softer media is the way to go.

If you have questions about your particular parts or finishing requirements, don’t hesitate to reach out to our experts for direction.

Get Started Today With Eaglemaster

Whether it is the final step or a preparatory one, finding the right steel shot blasting media for your parts is vital. Get in touch today to get a quote and expert advice on the best shot blasting strategy for your needs. Not sure shot blasting is what you need? Check out Eaglemaster’s other blasting services for even more options for your parts.