27 Feb How Centrifugal Barrel Finishing Works & When to Use It

Centrifugal barrel finishing (CBF) incorporates the use of g-forces into a barrel finishing setup. Parts are tumbled with abrasive media utilizing two spinning axles, creating nearly 10 times as much energy as traditional tumbling processes. Obviously, this makes centrifugal barrel finishing — also known as harperizing, thanks to the original CBF machines being made by the Harper company — a faster process, while also allowing for a much more controlled environment capable of precisely finishing higher-cost and more delicate parts.

Understanding Centrifugal Barrel Finishing

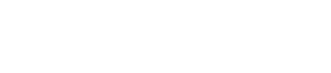

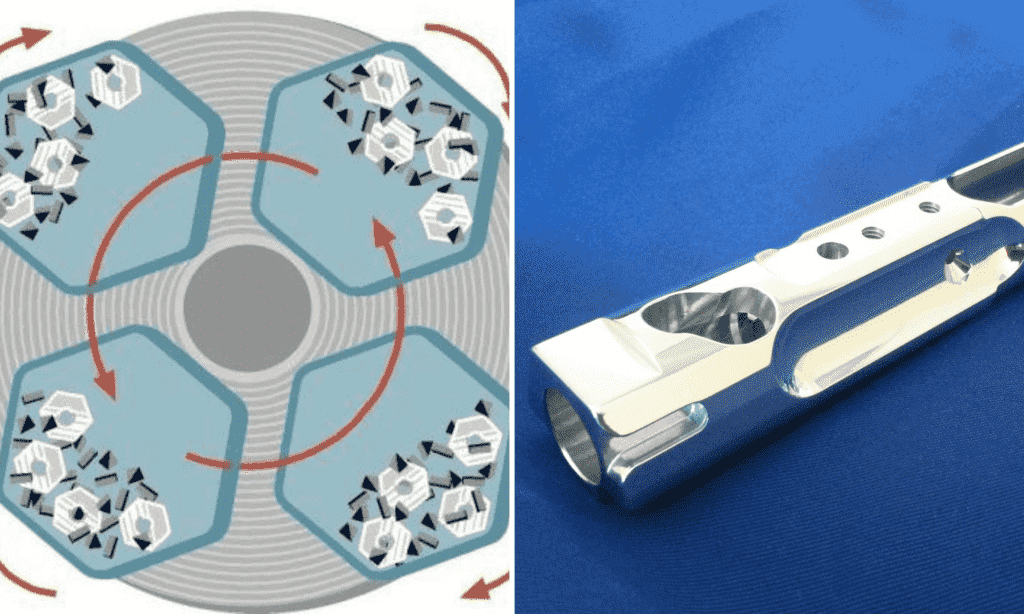

Centrifugal barrel finishing is similar in basic concept to traditional barrel finishing methods, in that they both use spinning barrel shaped machines. However, in the traditional method, parts and media are most often interacting and falling freely in the large barrel. Higher-energy harperizing machines utilize smaller pods on their own axles that combine with the rotation of the larger barrel to generate significantly more power while also allowing for refined control of the parts being finished. Centrifugal barrel finishing can produce a much smoother and more cosmetically appealing finish than traditional barrel finishing, while still removing burrs.

Specialized tape, tubing or even unique fixtures can be used to finish only the desired areas of a part while protecting the rest of the surface during the CBF process. This level of customization and precision gives centrifugal barrel finishing the edge over many other finishing methods.

The Machinery Behind Centrifugal Barrel Finishing

There are a variety of centrifugal barrel finishing machines that are used for different jobs based on volume, part size, power and controls. Some compact machines can fit on a table and are great for finishing smaller parts at lower volumes. Mid-size CBF machines have significantly more capacity and improved efficiency compared to compact options, but full- or super-sized machines are most often used for high-volume jobs and larger parts. High-efficiency and wide-barrel machines are also options for specific use cases.

The Process of Centrifugal Barrel Finishing

While it can seem complicated, the process of centrifugal barrel finishing can be explained in a few simple steps:

- Small containers are mounted on the edge of a larger wheel — like a ferris wheel inside the larger machine barrel.

- Parts, abrasive media and sometimes liquid (see below for more details) are loaded into each container.

- The wheel rotates quickly as the main barrel also spins, creating centrifugal forces much higher than the force of gravity.

- The pressure causes the parts and media to rub together and produce desired finishes in a short amount of time.

The difference between wet and dry centrifugal barrel finishing

Wet barrel finishing utilizes water along with other media to polish and finish metal components. Dry finishing only uses compounds and media. Both methods deburr and polish parts, with dry finishing producing a higher, smoother finish that is well suited for more delicate parts, and wet finishing resulting in a polished finish that looks less like it was done by hand.

Want to learn more? Check out our breakdown.

Applications and Benefits of Centrifugal Barrel Finishing

Centrifugal barrel finishing is used for parts across a huge range of industries including:

- Aerospace

- Automotive

- Jewelry

- Manufacturing

- Medical

- Technology

For all of these industries and more, CBF is used to remove burrs, smooth surfaces, improve surface quality and prepare parts for coating or additional processing. Across many industries, the benefits of smooth, uniformly finished parts are both aesthetic and functional, making harperizing a vital step in the manufacturing process.

When to Use Centrifugal Barrel Finishing

Choosing the right finishing process for your components can be a difficult decision, especially when you consider the various factors you must account for when the parts are finished. Things like component complexity, needed finish quality, volume of parts and required efficiency.

Centrifugal barrel finishing is excellent for parts that are too delicate or complex to be finished by traditional barrel finishing or vibratory methods, or for a high volume of parts that needs to be finished quickly. For many situations, the higher cost of CBF is offset by the time savings and high quality.

“Eaglemaster is a solid partner in the supply chain, they developed an intricate high-energy finishing process, which was outside the norm, to achieve the results we were looking for.” Multisource Mfg.

Burnsville– Zach P .

CBF With Eaglemaster

Eaglemaster offers high-energy, high-quality centrifugal barrel finishing services to meet all of your finishing needs. For parts that are more delicate or have complex finishing requirements, CBF is the way to go. It’s also a great choice for jobs on tight time or low micro-finish requirements that still need a highly cosmetic appearance.

If you want more information about centrifugal barrel finishing or want to consult with us about our other finishing services, reach out for a quote or to get your questions answered.