04 Jan Aluminum Restoration

Glass Bead vs. Aluminum Oxide Blasting for Aluminum Restoration

There are multiple blasting methods available to use in the aluminum restoration process, two of the most common being glass bead blasting and aluminum oxide blasting. These methods are widely used in aluminum restoration applications, especially in settings within the automotive industry. Restoring aluminum strengthens the metal and allows for parts to be painted, polished or otherwise finished in a uniform, repeatable way.

Glass Bead Blasting: The Gentle Approach

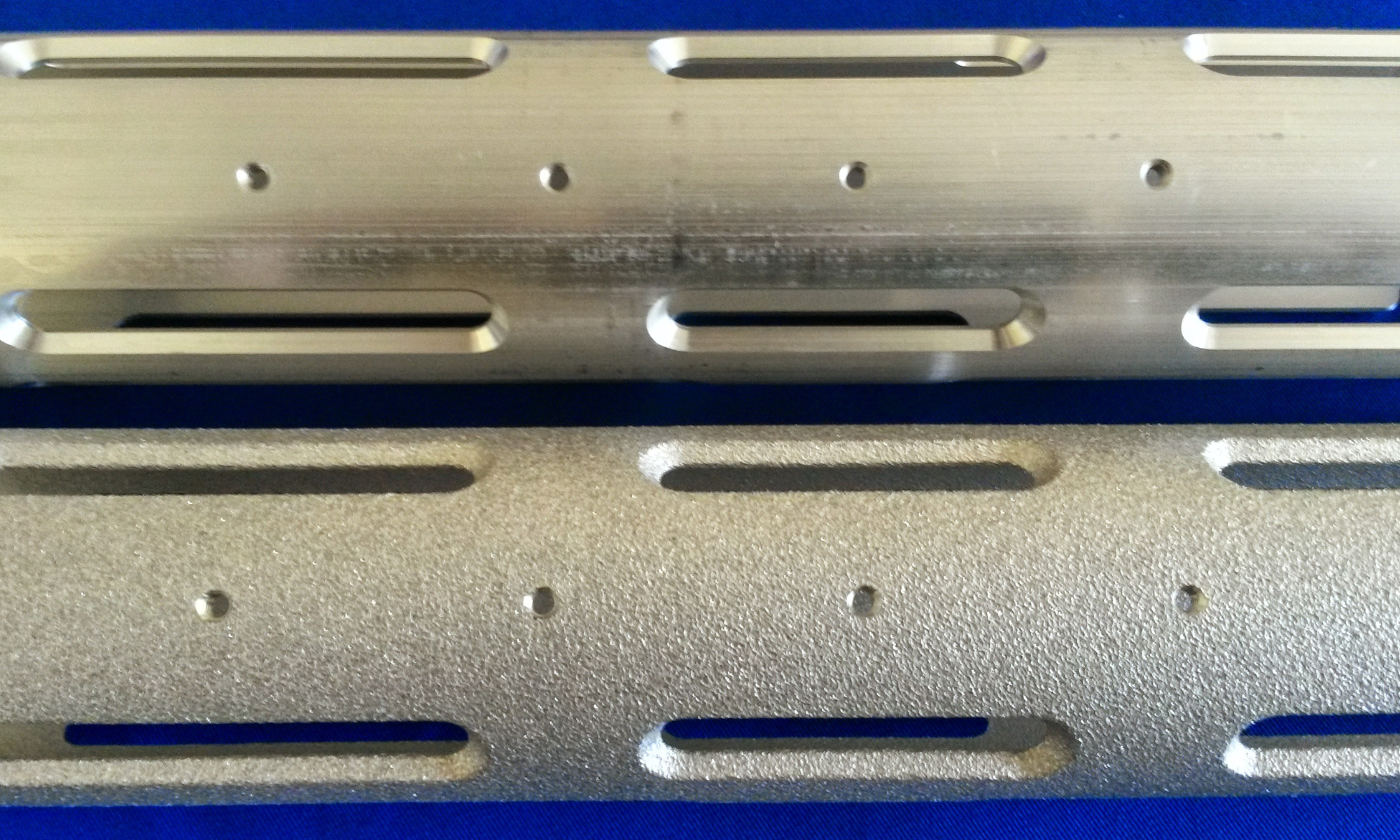

Glass bead blasting is the process of propelling very small beads of glass against an aluminum part that is contained in a specialized blasting cabinet. The operator uses a blasting gun that uses high pressure to project the glass media against the part. This is a highly precise technique that results in a polished, uniform surface. After using glass bead blasting on aluminum parts, the original color of the part will be lighter and the overall finish will be brighter.

Advantages of Glass Bead Blasting for Automotive Restoration

There are a number of advantages of glass bead blasting when it comes to aluminum automotive parts, including:

- Gentle cleaning

- Surface smoothing

- Light deburring

- Preserving aluminum’s integrity and overall aesthetics

- Uniform, polished finish

Limitations of Glass Bead Blasting for Automotive Restoration

While a useful technique, there are some potential drawbacks to glass bead blasting aluminum automotive parts. Some of the main issues include:

- Less effective against paint and parts with heavy corrosion

- Not a great preparatory process for further finishing or painting

Aluminum Oxide Blasting: The Stronger Alternative

Unlike glass bead blasting, aluminum oxide blasting uses grit-shaped, abrasive blasting media. The process is similar, the operator uses a blasting gun and the part will still go in a durable blasting cabinet, but the resulting finish will not reflect light, giving it a more matte appearance. When aluminum is blasted with aluminum oxide, the surface area of the metal increases slightly, making it more adhesive and receptive to further finishes after the blasting process.

Advantages of Aluminum Oxide Blasting for Automotive Restoration

Aluminum oxide blasting is excellent for many applications within the automotive restoration sphere, and performs especially well at the following:

- Removing corrosion and paint

- Creating surfaces suitable for adhesion

- Improving the durability and integrity of the aluminum

Limitations of Aluminum Oxide Blasting for Automotive Restoration

When choosing your blasting method for aluminum automotive parts, it’s worth considering some of the potential drawbacks of aluminum oxide, including:

- More aggressive abrasion can lead to some slight alterations to the parts

- Surface preservation is slightly sacrificed for better preparation for additional finishes