04 Jan Abrasive Blasting

Exploring the World of Blasting: Types, Techniques & Terminology

Blasting is a wide-ranging term that describes the process of propelling various types of media at high speed against the surface of parts to achieve a desired finish. Different types of abrasive blasting are used across a large number of industries for deburring, corrosion removal, cleaning, surface preparation, polishing and much more.

What Are the Types of Blasting?

While there are many different types of media that can be used in blasting, the most commonly used are shot blasting and the various types of abrasive blasting. We also offer more specialized blasting techniques that can be ideally suited to niche applications.

Sandblasting: The Classic Approach

Sandblasting is perhaps the most well-known version of abrasive blasting and is defined by the process of projecting sand particles from a high-pressure gun against the desired surface. Sandblasting is often used to remove rust, paint, and corrosion in order to prepare materials for further finishing, or as a method resulting in a finished polished surface.

One of the reasons sandblasting has been around for more than 100 years is that it is incredibly efficient and precise. However, this method has seen its popularity drop recently because of a growing number of health, safety and environmental concerns. The particulate created by sandblasting can cause major respiratory issues in workers if proper protection is not used, and even then the dust and heavy-metal residue created are dangerous environmental pollutants.

Abrasive Grit Blasting: Versatility and Precision

By changing the abrasive grit media used, operators have been able to develop alternative blasting methods to sandblasting that are safer and more environmentally friendly while still producing top-quality results. By choosing different sizes and variations of abrasive grit media, we are able to tailor the results in a number of ways. For example, blasting metal with aluminum oxide will result in a surface that is clean and primed for adhesion, making it perfect for anodizing or painting. On the other hand, blasting the same metal with glass will result in a bright, polished surface that is not as suitable for adhesive applications.

The overall variety of abrasive grit blasting allows it to be very versatile when it comes to materials it can be used with. It is also a very precise method of blasting, which gives the operator greater control over the outcome of every component. This is also one of the potential issues with abrasive grit blasting, as the specialized equipment and level of skill required means at-home or poorly trained operators have a greater likelihood of producing low-quality results.

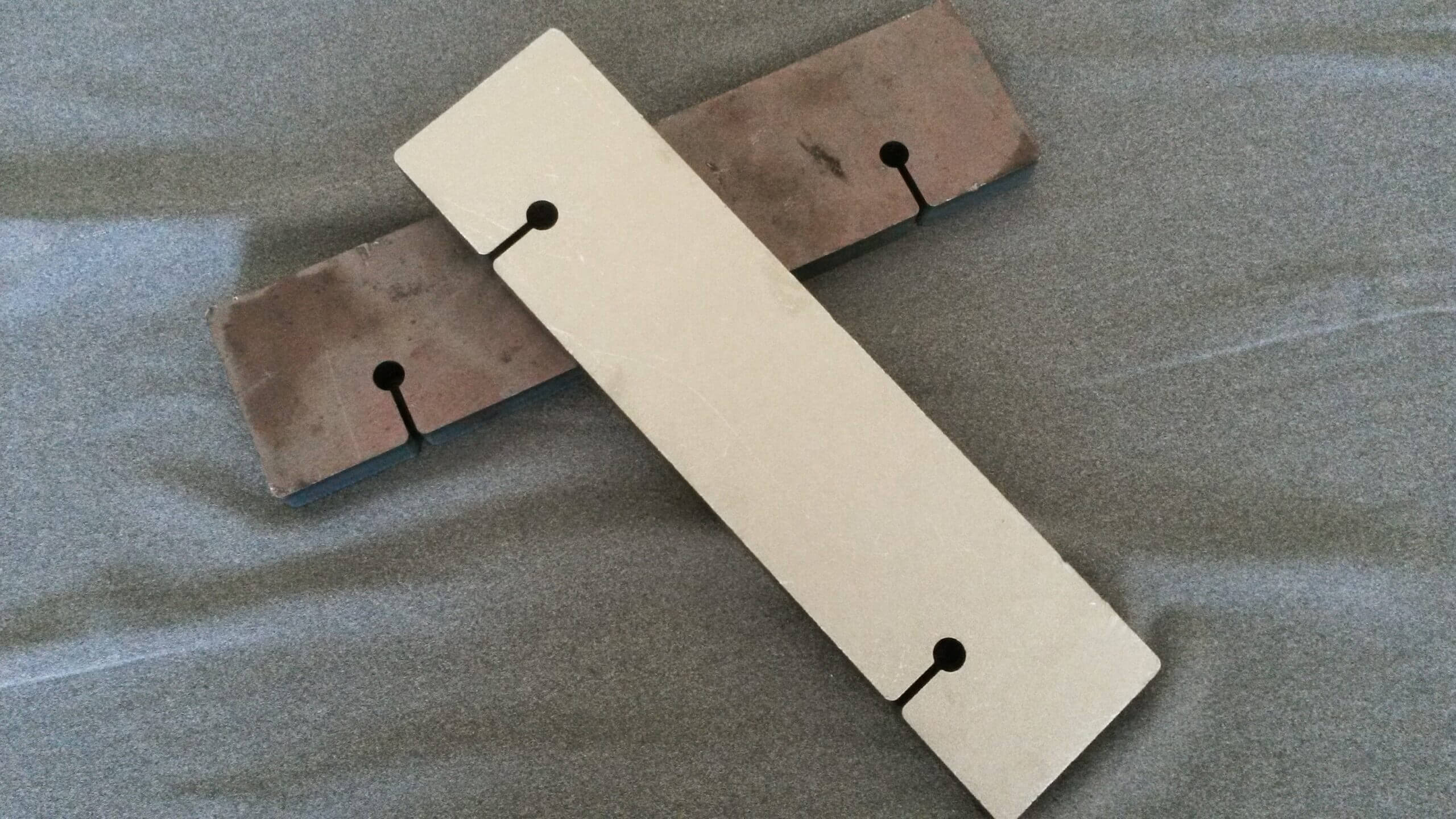

Shot Blasting Steel and Stainless Steel

Shot blasting steel or stainless steel focuses on cleaning, deburring and preparing the surface for further processing. This is an extremely cost-effective way of cleaning steel surfaces, although it does not drastically improve the part’s durability and strength like shot peening or similar processes.

Specialized Blasting Methods

Some of the less common, but still useful blasting media include plastic and ceramic bead. These media are generally used for gentle cleaning for surfaces and specialized applications that are not compatible with our usual types of blasting media. If you think your unique part might require a specialized blasting method, don’t hesitate to contact us!

Applications and Industry Uses

For many industries, blasting is a vital step for ensuring parts and components meet the standards for use. Eaglemaster provides abrasive blasting services across a large range of industrial applications, including:

- Aerospace

- Automotive

- Construction

- Manufacturing

- Medical

- And many more!

Explore the other various industries Eaglemaster works with and discover how we can serve you as well! On top of these various industries, abrasive blasting can be used for preservation, cleaning and surface preparation for a variety of finishes in many more situations.

Final Thoughts on Blasting Methods

When it comes to abrasive blasting, the amount of variables and options can feel overwhelming. However, knowing the broad concepts of how the blasting process works and the effects different media can have will give you a headstart in understanding what your own particular parts or components may need. For even more information and expertise, reach out to us — we can’t wait to hear from you!